“For Landri, we’ll be making the RIT arm. It’s designed specifically for people who have an elbow but not a wrist,” says eighth grader, Kyle Burton of Chesterfield. As a member of the tech club at Tomahawk Creek Middle School, Kyle gets to help improve people’s daily lives in a profound way.

This poised and mature young teen explains how Landri Peirce, a recent VCU graduate, will be able to control the grip of her new adaptive hand

by bending her elbow, a motion she’ll have to get used to through practice.

When I volunteered as an assistant in my son’s middle school library a year ago, I had no idea that I would find such an inspiring story. Like many school libraries, Tomahawk Creek Middle School’s media center serves as a meeting and work space for several different student clubs and organizations.

One day, while reshelving books, I couldn’t help noticing an energetic circle of kids working on what looked to be robotic hands from the future. These students were part of TCMS’s 60-member-strong technology club. Creating prosthetic devices for those who need them is just one of the remarkable projects this group undertakes.

One day, while reshelving books, I couldn’t help noticing an energetic circle of kids working on what looked to be robotic hands from the future. These students were part of TCMS’s 60-member-strong technology club. Creating prosthetic devices for those who need them is just one of the remarkable projects this group undertakes.

According to media specialist and technology club sponsor, Teresa Hockenberry, her students work with local experts to create adaptable hand and arm devices for amputees at no cost to the recipient. They do this through a global network of volunteers called e-NABLE.

No Experience Required

The room is abuzz with student led productivity. They have a new client, recent VCU graduate, Landri Peirce, whose left arm ends just below the elbow. I still can’t get over how mature and professional these kids are as they undertake the initial steps in developing Landri’s new limb.

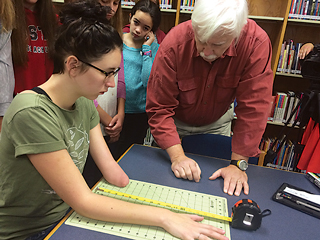

Bruce “Doc” Davies is the club’s mentor. Like an on-site Bill Nye or Inspector Gadget, the retired biochemist offers students his engineering expertise and guidance when they need it. As director of the MakerSpace at Chesterfield County’s central library, Doc was one of e-NABLE’s earliest proponents. His enthusiasm is contagious.

Doc estimates that through the combined efforts of Tomahawk Creek Middle School, L.C. Bird High School, and the public library’s MakerSpace, local volunteers have printed, assembled, and facilitated the fitting of twenty-two hands for people here in RVA, in other states, and across the globe. On a larger scale, e-NABLE community members throughout the world have used 3D printing to create more than 1,500 devices for people in fifty countries.

Doc estimates that through the combined efforts of Tomahawk Creek Middle School, L.C. Bird High School, and the public library’s MakerSpace, local volunteers have printed, assembled, and facilitated the fitting of twenty-two hands for people here in RVA, in other states, and across the globe. On a larger scale, e-NABLE community members throughout the world have used 3D printing to create more than 1,500 devices for people in fifty countries.

“Locally, it started out as an example program for our biomedical engineering club at L.C. Bird High School,” says Doc. “At first we just made hands for demos. About two years ago we began to link up with recipients and now all our hands go to folks in need. Many groups of individual students, home school students, Girls Scouts, and interested adults now make hands through the MakerSpace.”

In one corner of the school library, a few students are getting down to business, photographing and measuring Landri’s right arm and hand. A comfortable fit is paramount. Another essential step is to test Landri’s left arm strength, specifically gauging how much she can lift with the

two inches of forearm she was born with.

Another student enthusiastically opens her Chromebook to show me e-NABLE’s website. The site not only contains all sorts of information about the program, but also features design blueprints for volunteers to follow. They all have names based on their features and benefits. There’s the Raptor hand, the Talon hand, the Cyborg Beast device, the Limbitless arm, and Landri’s model, the RIT arm, named for the Rochester Institute of Technology professor who developed it. Each design can be customized to a recipient’s hand size, strength, and other specifications.

Another student enthusiastically opens her Chromebook to show me e-NABLE’s website. The site not only contains all sorts of information about the program, but also features design blueprints for volunteers to follow. They all have names based on their features and benefits. There’s the Raptor hand, the Talon hand, the Cyborg Beast device, the Limbitless arm, and Landri’s model, the RIT arm, named for the Rochester Institute of Technology professor who developed it. Each design can be customized to a recipient’s hand size, strength, and other specifications.

David Ellana is the principal of Tomahawk. He is just as amazed by these students as I am. “One of the truly neat things about this program is that it’s primarily student driven. We give them general parameters and guidelines, but it’s the students who are doing the creating, solving the problems, and doing the work. It’s amazing what they come up with.”

David Ellana is the principal of Tomahawk. He is just as amazed by these students as I am. “One of the truly neat things about this program is that it’s primarily student driven. We give them general parameters and guidelines, but it’s the students who are doing the creating, solving the problems, and doing the work. It’s amazing what they come up with.”

Open-Source Collaboration is a Win-Win

As if the life-changing potential of the student-led initiative isn’t impressive enough, it’s important to note that these middle schoolers aren’t just following the blueprints. They’re brainstorming, making advancements, and solving problems to improve people’s lives along the way.

For example, a few kids look on as one carefully removes the Velcro used to attach the RIT arm prototype onto its user. Now they’re replacing it with what looks like an elastic headband.

“We’ve noticed that the Velcro can get uncomfortable, rubbing against a person’s skin,” explains seventh grader, Eden Johnson. “So, now we’re experimenting with elastic athletic bands to see if they’ll work as well as the Velcro does.” She goes on to say that if the bands aren’t a suitable substitute for the Velcro, they’ll experiment with different types of padding to insert between the Velcro and the user’s arm.

If it works, the club will share their discovery on e-NABLE’s website for other volunteers to test. This modification, developed by Chesterfield County middle school students without engineering degrees, could become a standard part of the arm design.

Hockenberry says this kind of open source collaboration is a cornerstone of the e-NABLE program’s success. Unlike a typical project site, where the person in charge calls all the shots, everyone is working together to solve a common problem. “It’s been exciting to see them work to solve problems and learn from each other. The most touching times have been seeing their faces when they realize that something they did has made a difference in someone’s life.”

Function and Personality

As for Landri, this hip twenty-something hasn’t let being born with a little over half an arm slow her down. She is, however, looking forward to having another hand for balance while riding her bike.

“I learned about the e-NABLE program through a video on Facebook. It just looked really cool. I’d done some 3D printing for my undergrad thesis so I was familiar with the technology,” says Landri. “I was excited about the idea that they could make an arm that was lightweight and easier to use than the (prosthetic) arm I had when I was younger. Plus, it will be tailored to look the way I want it to.”

“I learned about the e-NABLE program through a video on Facebook. It just looked really cool. I’d done some 3D printing for my undergrad thesis so I was familiar with the technology,” says Landri. “I was excited about the idea that they could make an arm that was lightweight and easier to use than the (prosthetic) arm I had when I was younger. Plus, it will be tailored to look the way I want it to.”

The table in the media center, displaying half-a-dozen devices printed in a myriad of colors, makes it clear to me that these are not meant to be clones of human hands. “People get to choose the color of their new hands as well as any designs they’d like on them,” explains Kyle, a third-year member of the tech club. Landri has decided she wants a purple one.

When we think of more typical prosthetic hands and arms, we envision flesh-toned, high tech appendages that are cumbersome and not always user-friendly. Trying to keep the terms straight for these 3D models can be tricky, but after a sit-down with another tech club member I was enlightened.

“We’re careful not to call them prosthetics. We prefer the term ‘devices,’” offered eighth grader Austin Lubniewski. “People tend to think of prosthetic limbs as expensive and bulky and designed to try to look like they’re a real limb, but they’re not (real).The devices we make are simpler, but still really helpful.” To illustrate Austin’s point, another student handed me one of the device prototypes from the table. It was surprisingly lightweight.

Landri says this is what she finds appealing about the products of the 3D program. “Prosthetic arms are trying so hard to look like natural arms and they just don’t. It’s like they’re trying to hide the fact that they’re fake. I decided that if I had another arm, I’d want it to be raw and robotic and just be what it is.” She laughs. “If I’d been given the chance to have a robot arm when I was six years old, I would have loved that.”

These astute middle schoolers seem wise beyond their years in their ability to see things from the perspectives of their recipients.

“I think the fact that the hands we’re making aren’t designed to try to look like a real body part helps kids to feel more comfortable with them. No one’s trying to pretend it’s a real hand,” adds Ethan Hewitt, another technology club member.

Later, Doc told me about a kid who wanted a superhero hand device.

“Last year we made a Captain America hand for a little boy,” says Doc, with a grin on his face. “That’s what he asked for. So we ordered the plastic in the colors needed and printed and assembled the hand. The hardest part was making the shield and finding a way to attach it. But we did.”

Quick Hands Made to Order

With standard prosthetics, recipients can go through months of fittings and physical therapy in order to receive a new limb. By contrast, e-NABLE volunteers can customize, print and assemble one in just a few days.

According to Doc, the process is relatively simple. First, the students meet the person they’re helping so they can get to know them and develop a relationship. During this time, they take photos and measurements of the recipient’s other (natural) hand and forearm. “Then we use software to size the ‘standard hand,’ making changes for different sizes and anatomical needs. Next, the hand parts are 3D printed, which can take up to twenty-five hours. Once printing is completed, the parts are cleaned and assembled. Finally, we have another meeting to see how things fit and how well the recipient can use the hand. We like to make sure it works for them. And off they go with a new hand. But we stay in contact with them with time for growth or spare parts.”

High-Tech Simplicity

Even though they’re created on a 3D printer, this decade’s ultimate high-tech toy, the student-made hand devices are comprised of basic, easy-to-find materials: hard plastic, string, Velcro and small screws or bolts. This is a good thing, according to Kyle. “If someone breaks off one of their fingers, we can print a replacement for them. No problem. If they grow out of their device, we’ll just re-measure and make them a new one. ”

This is a big advantage over standard prosthetic devices, which can be out of commission for weeks if something malfunctions. Plus, insurance companies tend to pay for only one, which a kid can grow out of in just a few months.

Life-Changing Experiences

Hearing the students talk enthusiastically about their work and putting themselves in the shoes of someone a little different from themselves is really inspiring. I wish every kid could have the learning experiences that are part of a day’s work for these middle schoolers.

While I’m super impressed with what I’ve seen and heard about during the course of my interview (and yes, while eavesdropping as a library volunteer), Doc says it’s nothing compared to the day the tech club teams present their recipient with his or her new hand.

“It’s amazing, and I do not say lightly that it’s a life changer for those folks. Quite a few tears are shed, especially by the adults. The students are incredibly moved as well. They immediately try to get the recipient to ‘play with it.’ There’s ball tossing and everyone is scavenging things to be picked up. They’re all asking if it works and if it’s comfortable and looks okay and, and, and…”

Doc says it’s fairly simple for schools, churches, businesses and other organizations to join the e-NABLE community. Getting started requires a 3D printer, access to a computer with a CAD program, cameras, and a few hand tools. However, anyone can get involved and volunteer on their own through the Chesterfield Public Library’s MakerSpace. Doc is always happy to meet with schools to help them develop technology clubs or after school programs and to speak with those interested in receiving a 3D printed hand.

As my interview is about to wrap up, Doc issues a challenge to me and to everyone reading this article. “Come and build one. Be a part of giving it to a person. Then you can really understand what it’s all about.”